DIY Sparkplugs

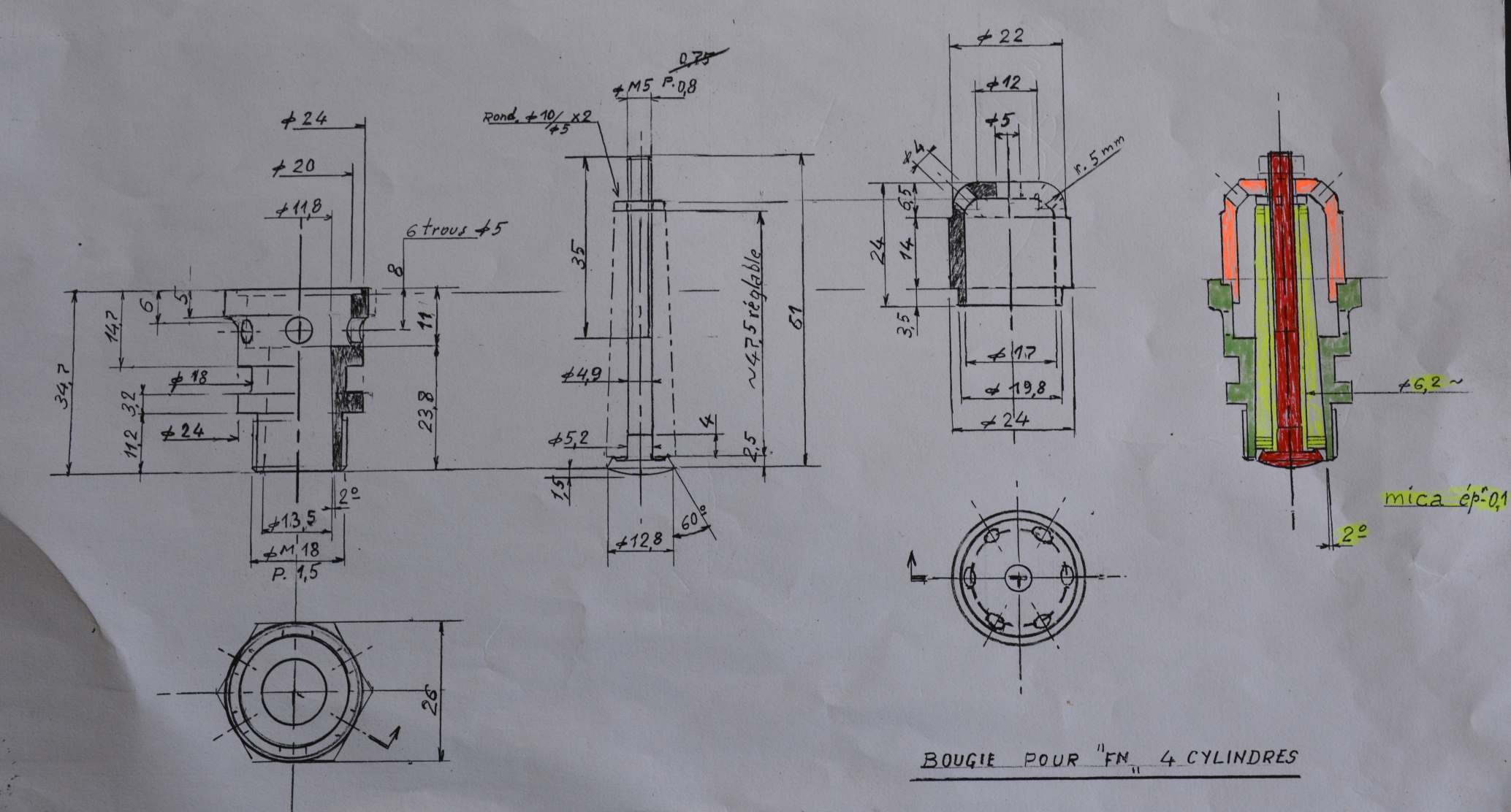

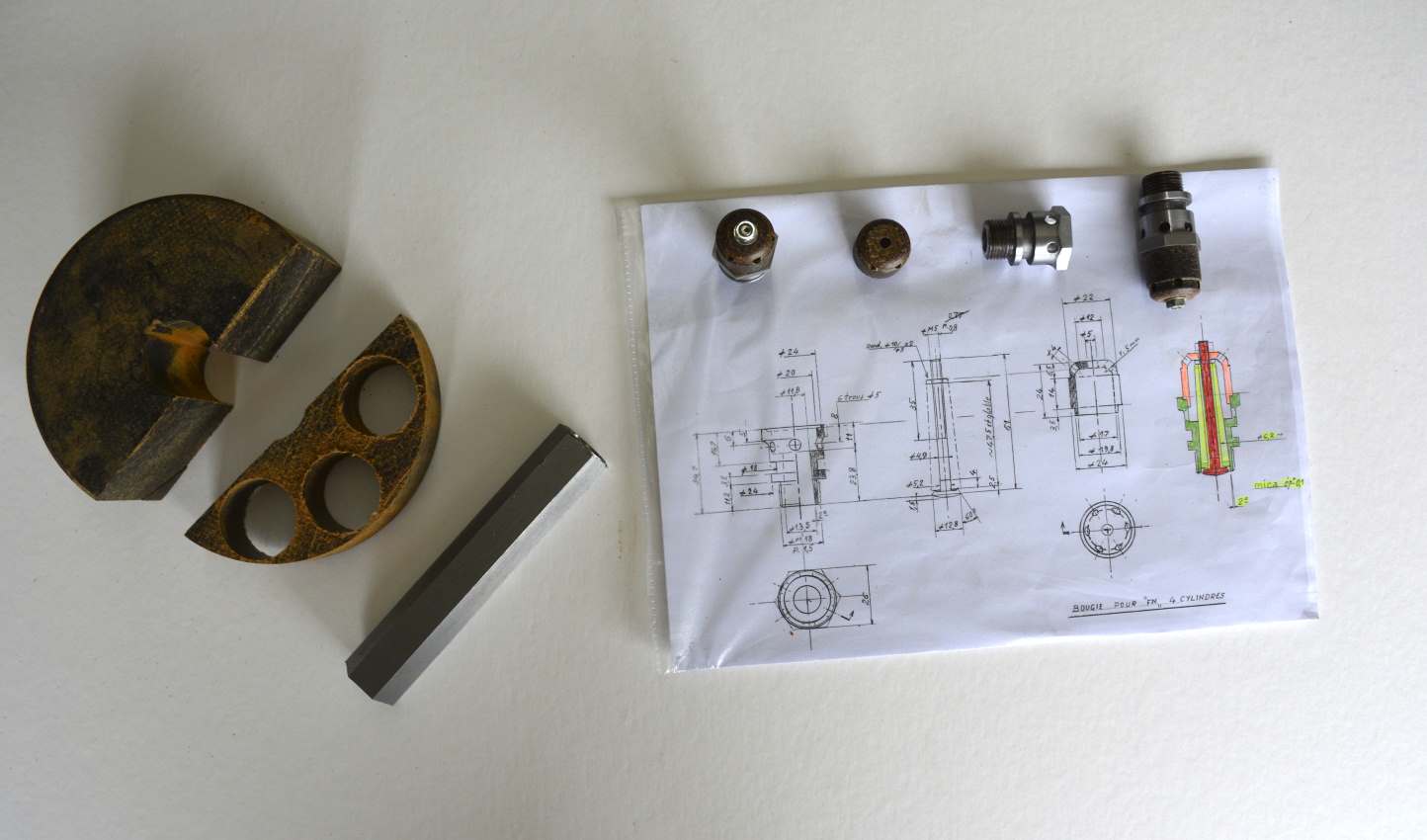

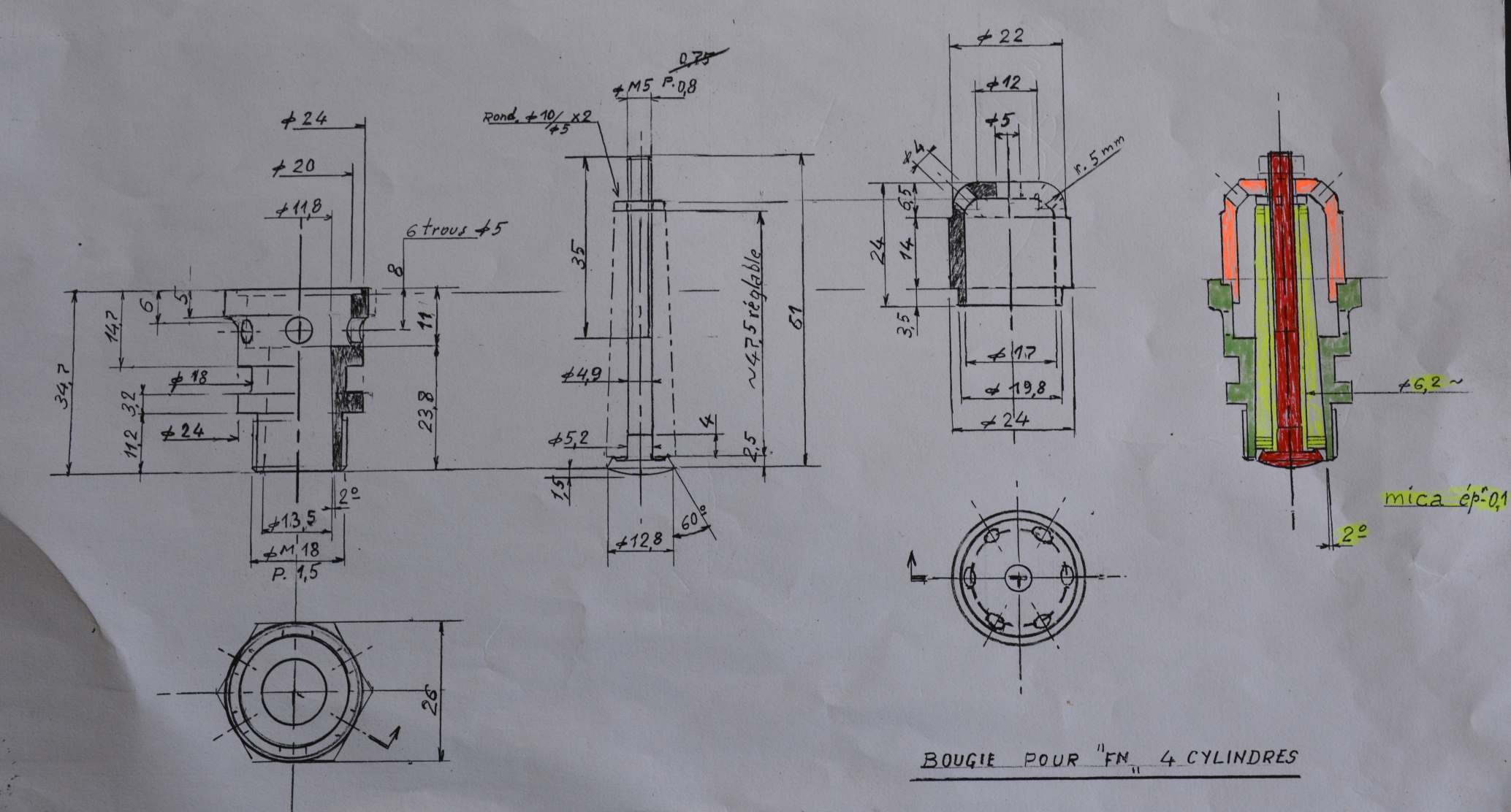

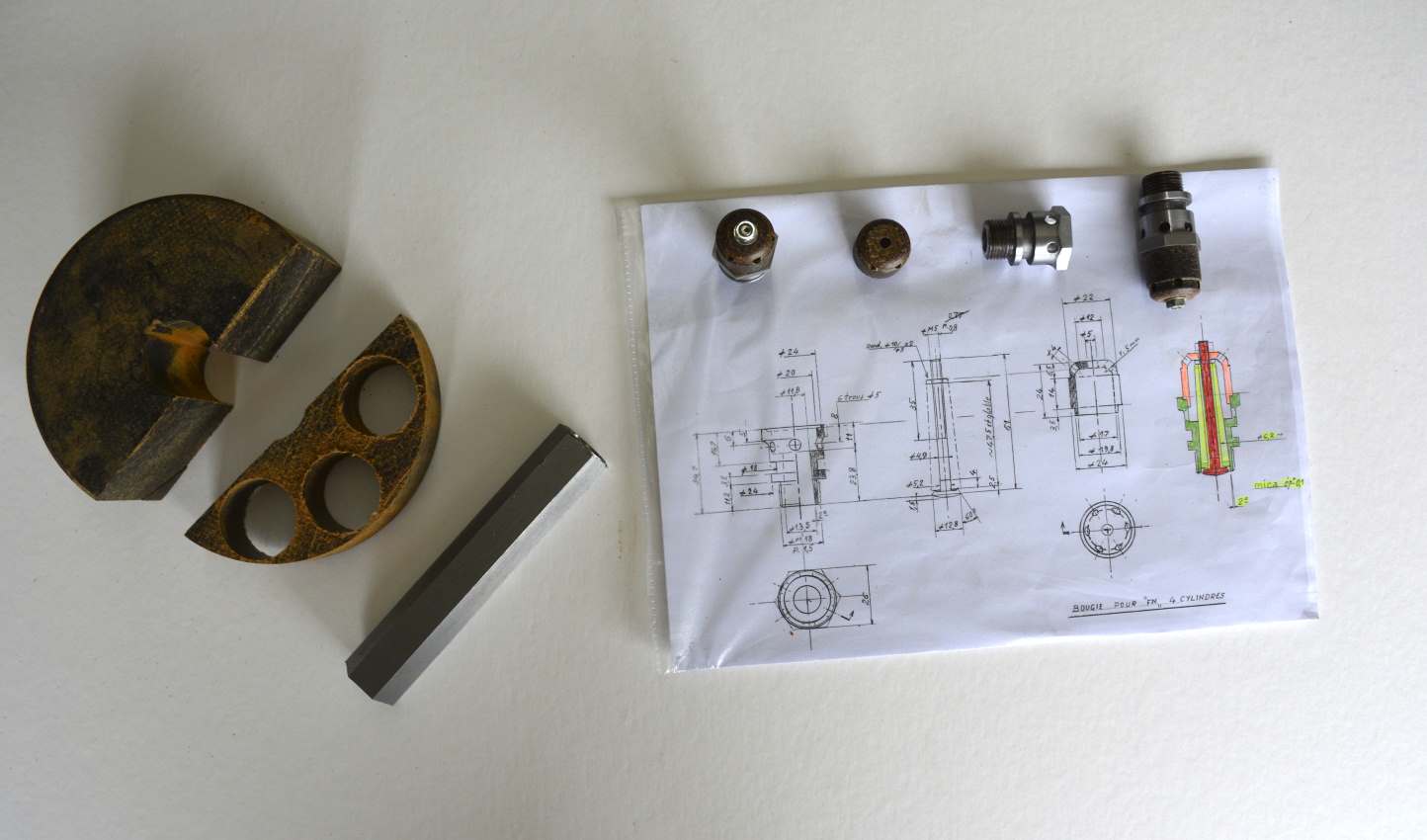

In 2012 when I arrived in Belgium, I met a fellow FN four enthusiast, Michel Bovy. I admired his original mica spark plugs and took photos, saying at the time I would like to see if I could replicate them. Lo and behold, the next day Michel presented me with working drawings of the spark plugs that a friend of his had created the night before. I was amazed how detailed the drawings were and kept them safe until two years later when I began about making a set.

I googled mica washer suppliers in India and received several responses. Despite their small size and little weight, the postage was expensive and a one-off tool needed to be made to cut the washers to size. I used hex steel to make the lower body which I threaded to 18mm and an internal taper of 2 degrees was machined to form a seal between the mica washers. These were of .2 + .1 thickness, mounted on a mandrel and ground with a matching 2 degree taper. I drilled cooling holes in the appropriate places.

The top cover was originally made from Bakelite or ebony, but as I did not have either material, I made my top cover from Tufnol, a manmade compressed fibre. The centre electrode is turned from a Grade 8 bolt. To adjust the gap (firing point), mica washers are either added or subtracted from the centre electrode.

When I used the mica spark plugs I was happy with the performance, but I found the heat range a little high. I've been studying the drawings closely and feel I need to remove some of the mica washers in the cover end to make them run a little colder.

It's not time consuming to adjust the electrode gap but I do need to put a dummy centre electrode in from the spark plug terminal end to keep the two degree taper in order. I am running .018inch gap. On the last run I did on the FN I used the spark plugs from my 2012 journey because I had constant stop-start city traffic and 330kms to travel with no time to make adjustments. When I get time to adjust the heat range I will let you know if the change improves their performance.

In 2012 when I arrived in Belgium, I met a fellow FN four enthusiast, Michel Bovy. I admired his original mica spark plugs and took photos, saying at the time I would like to see if I could replicate them. Lo and behold, the next day Michel presented me with working drawings of the spark plugs that a friend of his had created the night before. I was amazed how detailed the drawings were and kept them safe until two years later when I began about making a set.

I googled mica washer suppliers in India and received several responses. Despite their small size and little weight, the postage was expensive and a one-off tool needed to be made to cut the washers to size. I used hex steel to make the lower body which I threaded to 18mm and an internal taper of 2 degrees was machined to form a seal between the mica washers. These were of .2 + .1 thickness, mounted on a mandrel and ground with a matching 2 degree taper. I drilled cooling holes in the appropriate places.

The top cover was originally made from Bakelite or ebony, but as I did not have either material, I made my top cover from Tufnol, a manmade compressed fibre. The centre electrode is turned from a Grade 8 bolt. To adjust the gap (firing point), mica washers are either added or subtracted from the centre electrode.

When I used the mica spark plugs I was happy with the performance, but I found the heat range a little high. I've been studying the drawings closely and feel I need to remove some of the mica washers in the cover end to make them run a little colder.

It's not time consuming to adjust the electrode gap but I do need to put a dummy centre electrode in from the spark plug terminal end to keep the two degree taper in order. I am running .018inch gap. On the last run I did on the FN I used the spark plugs from my 2012 journey because I had constant stop-start city traffic and 330kms to travel with no time to make adjustments. When I get time to adjust the heat range I will let you know if the change improves their performance.